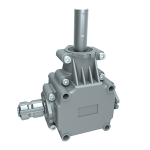

Servo Worm Reducer

Cast Iron Worm Reducers

Stainless steel worm reducers

Advantages of EP Worm Gear Reducers

Exceptional Cost-to-Torque Ratio. Engineers typically select reducers by comparing their cost to the torque they provide. Worm gear reducers are perennial champions as far as returning torque for the buck. Why? Because they provide more input shaft rotations per output shaft rotations. In a single stage, a worm gear reducer can commonly deliver 60:1 gear reduction. A helical reducer, in contrast, would require three stages of gearing to produce such speed reduction. With fewer gears and bearings involved in a single stage, worm reducers cost less to implement.

Widely Available and Easily Interchangeable. Gear manufacturers (including EP tend to maintain a broad inventory of worm gear reducers. Moreover, worm gears’ mounting dimensions are universal across manufacturers; gear ratios have also been standardized. With worm gear reducers, engineers don’t have to fret over the shaft height, length, or diameter. Dimensional consistency facilitates worm reducer replacement.

Fewer Moving Parts than other Load Break Options. The simplicity of worm gear designs is an advantage. The more complex a system, the more opportunities for failure.

Flexible Mounting Choices. In a worm gear reducer, the gear is mounted on the output shaft at a 90- degree angle to the input shaft. This frees up both ends of the output shaft for more engineering design options. Moreover, both solid and hollow output shafts may be used with worm gear reducers. Hollow output shafts are gaining popularity, as they remove the need for belts or chains which transmit torque from solid shaft reducers. Again, fewer moving parts translates to less need for repair.

Lower Noise Levels. Sudden gear tooth contact is common in bevel and helical gearing; this creates ambient noise, which plant managers must minimize to meet EP industrial hygiene standards. Worm gears run more quietly because the gear teeth slide into contact with each other, and because there are always more gear teeth touching the gear mesh. Moreover, because a worm gear will require a single stage where other reducers would require two or more gear stages, less noise is created overall.

worm reducers

As one of leading worm reducers manufacturers, suppliers and exporters of mechanical products, We offer worm reducers and many other products.

Please contact us for details.

Mail: [email protected]

Manufacturer supplier exporter of worm reducers.